Murphiller

PRODUCT DESCRIPTION

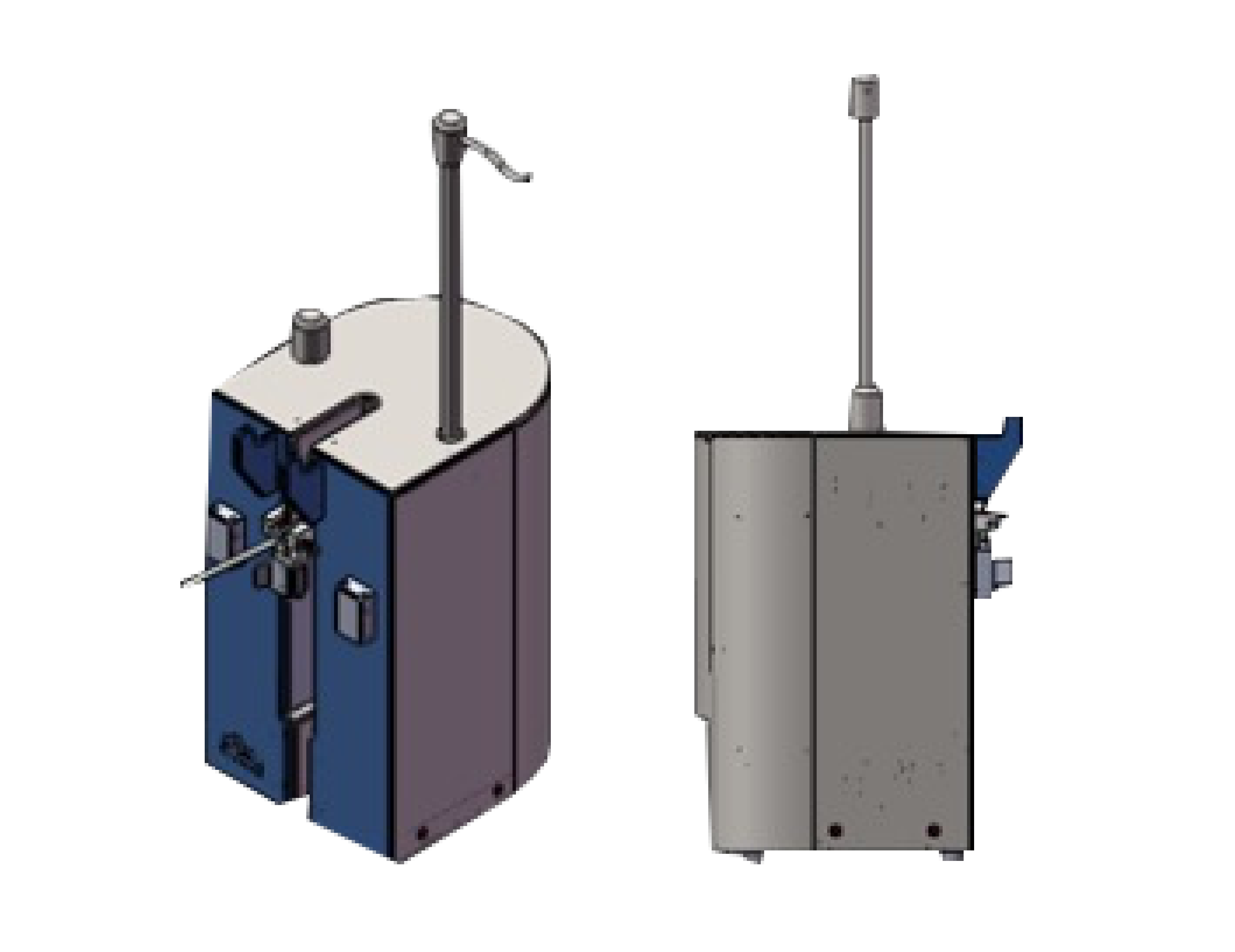

Dose Dispenser & Dose Calibrator in one instrument. State of Art, Patented technology uses real time activity measurements for dispensing.Project Details

MurPhiller Dispensing systems family

MurPhiller is a family of radiopharmaceutical dispensing systems. The heart of the project is the Patented detector, called STEM CHAMBER. The particular and unique shape of the STEM CHAMBER allows to reduce the dimensions of the device, to have an optimal accuracy, in order to maximize the ergonomics.

Main components

The MurPhiller dispensing unit is composed of two main components:

- Filling unit

- Control PC

The filling unit is responsible for determining the activity set by the user for the filling of the syringe and for performing the exact filling in the shielded syringe/vial.

The unit has an internal microprocessor based electronics, including a dedicated firmware, performing all the tasks required for the syringe/ vial filling.

Its main components are:

- Physio holder: this is where the saline solution is placed

- Physio pump: is the high speed peristaltic pump responsible for pushing saline solution into the syringe or vial

- Syringe/vial sliding holder: holder for syringe/vial housing

- Radiopharmaceutical pump: is the low- speed peristaltic pump, responsible for pushing the radioactive compound into the syringe/vial

- Measuring chamber for syringe/vial: dedicated measuring chamber where the destination syringe/vial is placed. It is responsible for measuring the activity that is going to be dispensed in the syringe or vial

- Integrated measuring electronics: long life remotized electronics control board.

Technical specifications

- Dimensions and weight: 220 mm (w) x 210 mm (w) x 370 mm (h), weight around 15 kg

- Anodized aluminium construction

- Stainless steel chamber

- Power: 110/230 Vac, 50/60 Hz

- No need for gas or compressed air supply

- Two independent peristaltic pumps

- Electrometer Linearity: ± 2% over full range

- Electrometer accuracy: ± 2%

- High voltage readout

- Electronic zero control and adjustment

- Background measurement and compensation

Disposable kit setup is performed once the kit itself is properly introduced and opened in a class A environment.

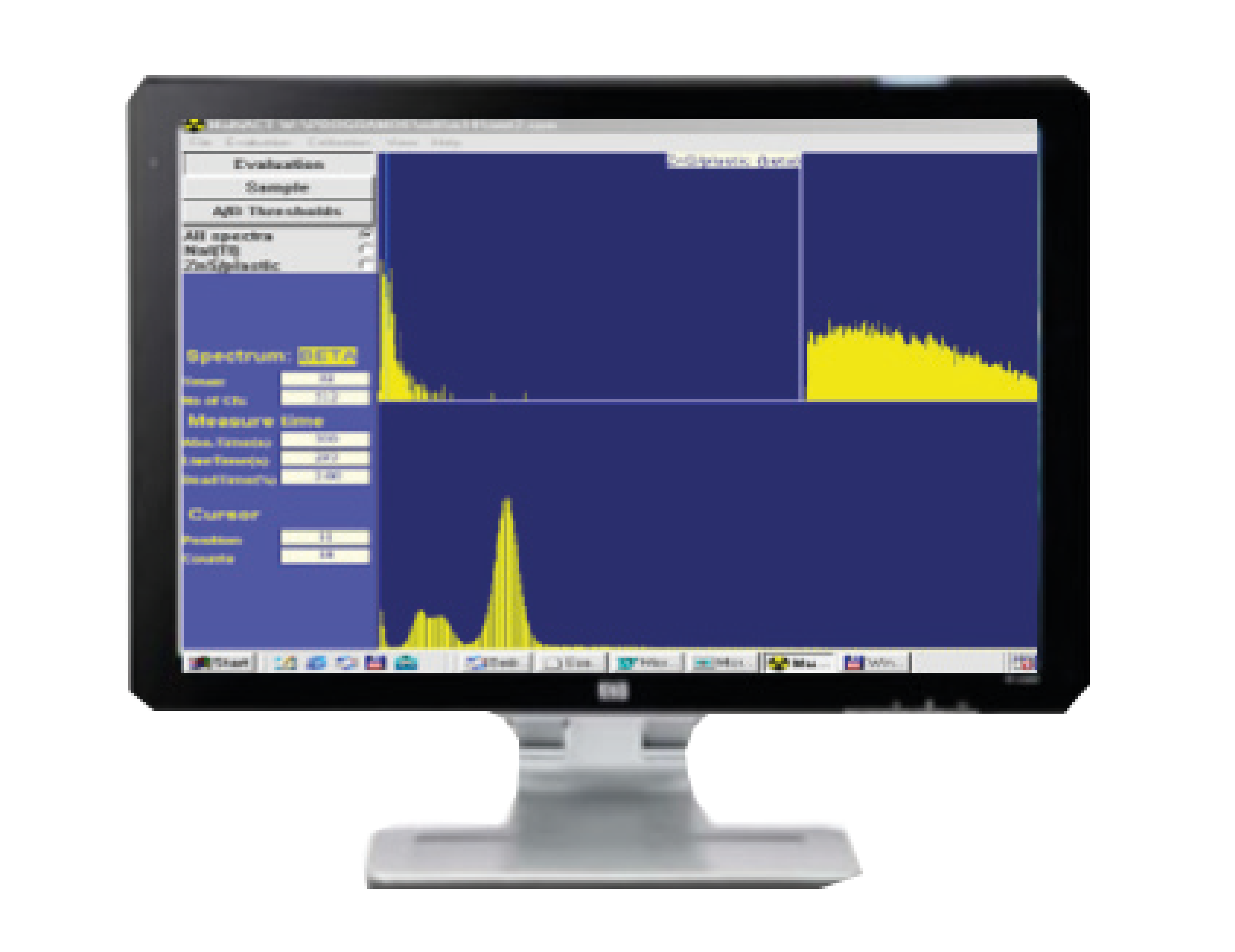

Software

The system is fully controlled by a full featured software running over an external Laptop PC. The software main specifications are:

- Easy to use

- Password protected

- Real time activity measurement of the sample inside the chamber

- Setting of required activity

- Permanent SQL database storage of isotopes, geometries and calibration factors

- Full suite of QC routines (linearity, accuracy, calibration, High Voltage, Electronic Zero, background), in line with international regulations of measuring devices (Dose Calibrators)

- Fully compliant software with product regulations

- Intuitive user interface

- Real time control